Galli Uhren Bijouterie AG

Theaterstrasse 16, on Bellevue

CH-8001 Zurich

Tel: +41 44 262 04 10

Fax: +41 44 252 49 96

Seals of Quality and certifications of mechanisms have been around for a long time in the Swiss watch industry. To gain an overview, I will summarize the well-known features.

The COSC-certification is the best-known in the entire watch industry. Brands such as Omega, Breitling, Tudor, Longines, Rolex, Oris, and Tissot have their mechanisms checked by the independent official Swiss inspection office. There, the mechanism is checked for accuracy in different altitudes and temperatures also. The whole process takes up to 15 days.

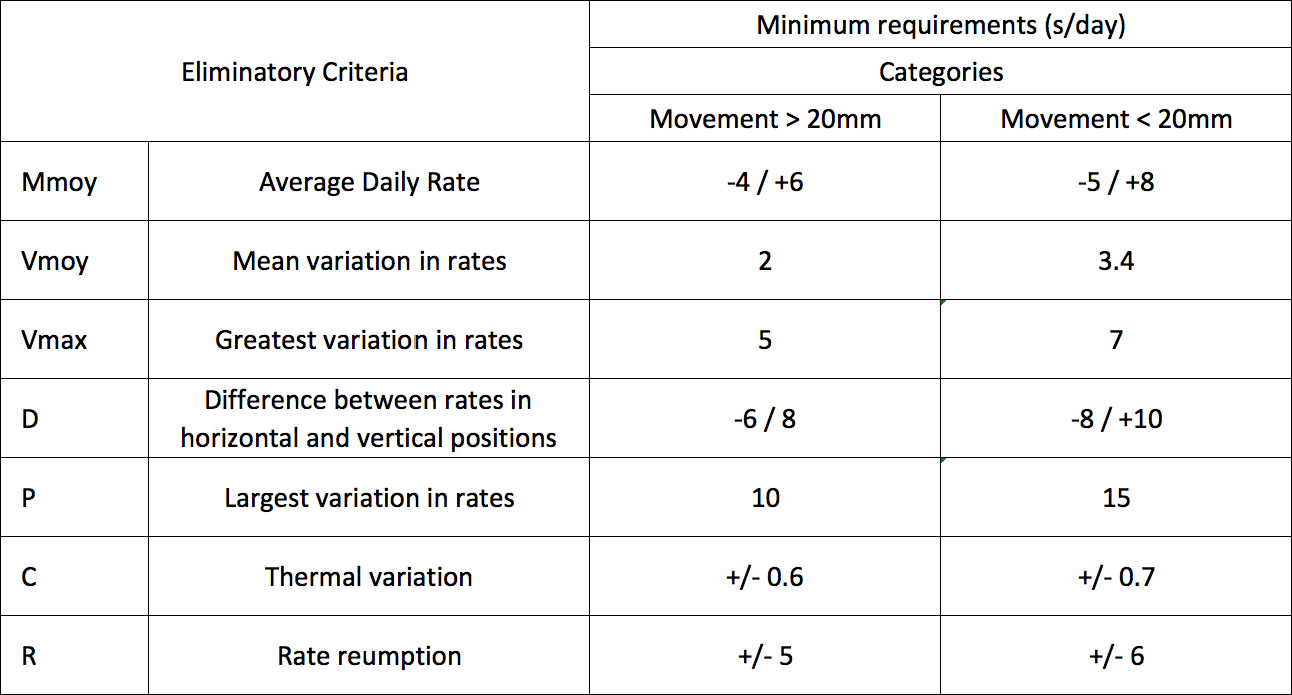

The average daily deviation should not be greater than -4 or +6 seconds per day as shown in the table below. The control office has been around since 1878 and has audited 1.6 to 1.8 million mechanisms in the last years.

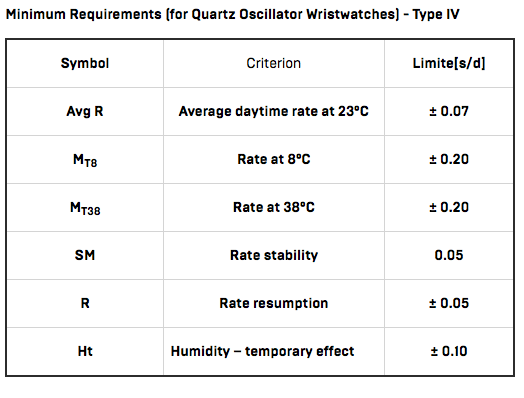

In addition to the mechanical works, COSC also checks quartz watches for accuracy. In an approximately two-week test procedure, they are tested under different temperatures and humidity, among other criteria. For more details, see the following table:

As can be seen above, the precision requirements for mechanical works with a movement diameter smaller than 20 mm are less specific.

After the test result was successful, the manufacturer may officially designate the watch as a chronometer. Whenever a watch lover is looking for a precise mechanical wristwatch, a chronometer-certified work is a must.

In addition to the mechanical works, COSC also tests quartz watches for accuracy. They are tested for a total of 13 days at different temperatures and humidity. For more details, please see the following table:

After the test result was successful, the manufacturer may officially designate the watch as a chronometer. Whenever a watch lover is looking for a precise mechanical wristwatch, a chronometer-certified work is a must.

METAS, the Federal Institute of Metrology, realizes and specifies internationally harmonized and recognized units of measurement with the required accuracy. Currently, METAS only certifies Omega watches. The entire testing period takes around 10 days and is initiated after the 13-day COSC certification. Consequently, the trial period of a Co-Axial Master Chronometer lasts about 1 month after production. In accordance with the COSC certification, the following is tested:

The remarkable thing about the entire testing process is that a strong magnetic field must not affect the accuracy of the clock. In addition, the power reserve is checked as well. Unlike the COSC, the mechanism is already in the case during the entire testing phase.

The Poincon de Geneve has been around since 1886 and is one of the most conservative quality seals. The reason for this is that the production, assembly, and regulation of the mechanism are exclusively carried out in the Geneva cantonal territory. It is distinguished especially by its aesthetics because most of the individual parts must be sanded and polished by hand. Accuracy is of less importance since only an accuracy of one minute per day over a 7-day period is specified. Therefore, watch mechanisms such as Vacheron Constantin, Cartier, Chopard, and Roger Dubuis display the Geneva stamp.